Let’s start our conversation with these questions:

- I know how to climb Mount Everest but can I do it?

- I know how to negotiate a big deal but can I do it?

- I know how to handle labor unions but can I do it?

You will find interesting references on “Linking Knowledge to Action” on the internet.

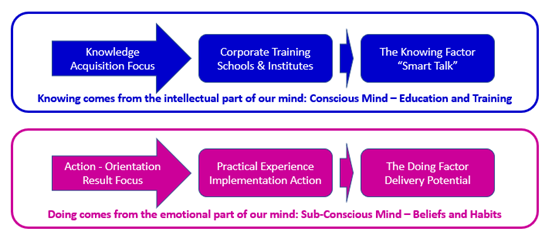

How do smart companies turn knowledge into action — and what stops others from doing the same? Over the years, I’ve met many executives, managers, and engineers who were smart and hardworking, but who were unable to turn their improvement ideas into organizational action. It was found that while many knew what they ought to do, actually putting their ideas into action was a completely different ball game. Adaptation to context is the tricky part of the execution. KNOWLEDGE ALONE DOES NOT CONFIRM ABILITY TO ACT.

The puzzle – despite several degrees and training, managers find it difficult to turn knowledge into organizational practices, services, and business models. Corporate training spends $40+ billion in the US; India spends between $2-4 billion. Besides this, much money is spent on consultants and advisors. Most recommendations from consultants are good, but the ability to tweak the inputs to suit a specific context will depend on the wisdom of the leader. A LEADER’S WISDOM ON IMPLEMENTATION ABILITY AND ACCEPTABILITY IS CRUCIAL TO SUCCESS.

Most people at the top are privy to information from market research and intelligence. They are aware of business models, practices, and technologies that are being used by their competitors. However, despite the wisdom and knowledge, many leaders are unable to manage implementation in their spheres of work. What could be the reason that holds them back? It was found that in most cases the context was not conducive to adaptation. LEADERSHIP ACTION IS LIMITED BY THE CONTEXTUAL CONSTRAINTS.

Auto Industry Example: Every automobile executive knows about John Paul McDuffey’s research and a book called “The Machine that Changed the World”. This book convincingly outlines what an ideal automobile plant looks like – the Toyota production system. (McDuffey followed every automobile plant in the world for over a decade and found that Toyota produces higher quality cars at a lower cost). Despite having such knowledge, executives in other automobile companies could not coax their plants to implement these methods as effectively as Toyota did. LINKING KNOWLEDGE TO ACTION IS NOT A SIMPLE AND STRAIGHT FORWARD EQUATION.

Failure to implement does not happen because leaders lack intelligence or persistence; rather, it is because they lead organizations with different cultures and contexts, that make these changes untenable to implement. A study on the so-called “War for Talent”: McKinsey Consulting surveyed the corporate officers of 77 corporations. They found that employees stay longer and are happier with their jobs when line managers are involved in recruiting people for positions. However, most recruiting is handled by “Human Resources” alone. The research showed that 78 % of officers surveyed believed that line managers should be held accountable for the quality of their people; only 7 percent reported that their companies actually used this practice. We also find that most candidates have knowledge, experience, and wisdom in different areas, however, it is often difficult to distinguish between the three. Involving line managers in recruiting will reduce misinterpretation of culture and context. LINKING KNOWLEDGE TO ACTION MUST CONSIDER THE CONTEXT, CAPABILITIES, AND ATTITUDES AT ALL LEVELS.

A ground reality “Zero Defect” – Case Study (Middle Management)

A divisional manager from a multinational organization joined a medium-sized family-owned business. On his orientation rounds, he found that the cylinder head production line was not working as efficiently as it could have. This line was set up with machinery imported from Germany. On investigation, he discovered that one of the bottle-neck machines was producing 100% defective parts which had to be reworked to rectify the defect. He found out that the machine received had been defective from the beginning and nobody questioned the malfunctioning for the past 25 years as it was from Germany. (German imperfection was inconceivable) In 3 months, he solved the problem by rectifying the machine misalignments and brought the defects to zero.

PROMPT-O DRIVERS used in Zero Defect – Case Study

- Leaders Pursue end results with commitment: Based on his knowledge and past experience the division manager (DM) pursued “Zero-Defect” end result with commitment.

- Leaders are Risk–aware (consequences and mitigation): The DM was aware of the risk involved in going against the past management acceptance of a German machine producing 100% defects for 25 years.

- Leaders are Outcome-oriented (Focus on the destination, not process): The DM never lost sight of the outcome vis a vis cost savings (manpower, machine, and consumables utilization) and reduction in production cycle time

- Leaders formulate Messages that make intentions clear, simple, and specific: The DM made his goals, objectives, and approach to all involved through easily understandable messages. This brought team synergy towards goals.

- For leaders Practicality supersedes perfection. Consideration on overall effectiveness: The DM promoted practical approaches instead of going for the perfection paralysis route. This facilitated progress and team spirit.

- Leaders Track progress on critical parameters only: The DM focused on parameters critical to progress to ensure resources and energy was used for the right purposes and direction.

- Leaders are open to advice and constant learning: The DM was open to advice and ready to learn from multiple experienced professionals at all levels. This helped to resolve many problems, big and small, along the way.

The Action Advantage: There is no knowledge advantage unless it leads to an action advantage.

A learning organization is useless unless it’s also a doing organization.” Starbucks President Howard Behar

Data: Isolated facts; Information: Connected theories: Knowledge: Awareness of applied theories without practical understanding; Observation: Exposure to applied theories in action; Action: Personal situation experience leading to skill; Experience: Multi-skill practice in specific situations; Learning: Understanding influencing factors in practical situations; Comprehension: A holistic appreciation of situations and skills involved; Wisdom: Ability to apply comprehension across situations.

Bottom line: Linking knowledge to action is easier said than done. Leaders need to take the support and advice of many experts in different functional and technical professions. Successful leaders develop their own circle of consults for support in taking decisions on moving from knowledge to action. This would be specific to cultures and contexts. Integration and balance of advisory inputs call for a high level of leadership skills and wisdom. Successful leaders follow the “PROMPT-O drivers” approach.

Let me stop here and ask, What constraints have you come across in linking knowledge to action?